Needle Tips

General Information

![]()

Domestic sewing machines today basically use the one needle system (705/130H, HAX1, 15X1) but they are available in a large variety of sizes and point styles. Selecting the right needle and thread for the fabric you plan to sew is one of the most fundamental steps to achieving a successful stitching result.

Machine Needles come in sizes ranging from sizes Metric Size 60 to 120 (Imperial Sizes 8 to 20). This size essentially represents the thickness of the needle. The lower the number, the finer the needle. Thread, however, is the opposite, the finer the thread, the higher the number.

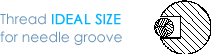

When sewing, the thread lies in the needle groove, if the needle is too fine for the thread, the thread will not fit into this groove causing faulty stitching.

The needle must also be in perfect condition. Stitching problems occur from using a needle that is either blunt, bent or if the tip has been damaged.

Problems

Machine is noisy when stitching.

Machine is skipping stitches.

Seams pucker when stitched.

Machine is jamming.

Upper thread is often breaking.

Tension seems/appears unbalanced.

Needle Breakage

“It is true, that the higher the quality of the needle, the more likely it will break, and a low quality needle will almost never break but bend!”

Why is this so? A machine needle is a precision made tool, which is designed to perform within very fine tolerances and at temperatures that vary from room temperature to over 200 degrees Celsius (550 degrees Fahrenheit). One of the performance criteria’s for a quality needle is that it must break cleanly when deflected more than 15 degrees from it’s original vertical position.

The reason for this is that the needle is operating within very fine clearance of the sewing machine hook mechanism, and this expensive and critical part of the sewing machine must be protected from damage. If the Hook (which catches the needle thread and carries it around the bobbin to form the lock stitch) is scratched or damaged by the needle, this could result in stitching and tension problems and ultimately an expensive repair bill for your machine.

If during the stitching process, the needle is deflected more than 15 degrees, or if it is bent and remains bent it is likely that damage to important parts of the sewing machine will result.

So good quality sewing machine needles are designed to break when something is wrong, so as to protect the expensive mechanism of the machine. When a needle breaks regularly, look for the cause – don’t blame the needle!

Possible causes of needle breakage

Needle is too fine for fabric.

Stitching over pins or zippers.

Wrong needle system for machine model.

Upper tension is too tight.

Bobbin case or bobbin incorrectly fitted.

Presser foot is loose and not properly fitted.

Needle not properly set or is loose.

Fabric is too thick and does not match needle in use.

Pulling fabric without raising the presser foot after sewing.

Needle Size And Thread Diameter Relation

| In general the sewing thread diameter should be about 40% of the needle size (Nm).The reason for this is the ratio of the needle size to the cross-section of the long groove. | ||

|

||

|

||

|

Needle Markings

![]()

We are delighted to introduce coloured shanks as a new standard feature across the Klasse needle range. This outstanding and distinguishing new feature, is the only range wide colour system available. All Klasse needle point styles are now easily identifiable by consumers and retailers alike. The Klasse brand is now even more consumer friendly.

With this new colour shank system, consumers will always know what style of needle they are sewing with. This colour system is completely unique to Klasse and Hemline needles.

Sewing Machine Needles Explained

Sewing Machine Needles Explained. Which sewing machine needle to use. Welcome to the first of many ‘Straight to the point’ knowledge & understanding videos and how apt to start with Sewing Machine Needles!